28 Aug 2010

27 Aug 2010

Growing tobacco

We've experimented with growing tobacco over the last three years, and had good success with growing and drying. However, we haven't yet found a device or cutter that will make it possible to cut very finely for cigarettes, like commercial hand-rolling tobacco. Nonetheless, this is a lovely plant to grow.

The seeds require warmth to germinate, but tobacco grows well in the UK.

Tobacco seeds and seedlings are tiny.

They grow fast.

Grow in pots, inside or outside; or grow outside in the ground.

Beautiful flowers

Beautiful roots

Beautiful leaves

Pressing and cutting

We read of and tried a method used by sailors, who used to wrap rope or twine around rolls of tobacco leaves to allow them to mature under compression. They cut slices from the end to smoke, rubbing the slices to open out the strands. This came to be called 'navy cut' tobacco.

Navy cut.

The two on the left are commercial cigarette rolling tobaccos. The one on the right is ours. It's OK for a pipe or cigar filler, but it needs to be much finer for cigarettes.

Buying seeds

We bought our tobacco seeds over the internet from Plantation House. We bought Maryland 609, Virginia and Monte Calme Yellow seeds; all suitably light for cigarette tobacco. There is a great deal of information on their site, as well as a forum of growers.

The law

The position with growing and using tobacco in the UK seems to be that if it's for personal use, no one's going to trouble you.

This is from a letter sent by Customs & Excise to Plantation House in October 2001:

Additive-free tobacco

A major consideration with growing your own tobacco is that it can be organically grown and additive-free.

In 2006, Gallaher listed on their site 366 additives to their cigarette tobacco. However, later that year they were taken over by Japan Tobacco, who don't list the info on their site (they state that that section of the website is currently under construction - at 22/04/09).

[Update 21st July 2011: The Japan Tobacco site now shows the ingredients added to tobacco. The info for the UK is here.]

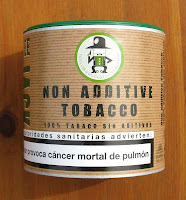

If you are not growing your own and you want to smoke tobacco without additives, you can buy Free Jack Non-Additive Tobacco (that's 'non-additive', not 'non-addiCtive'). This one is sold in Spain, but a Dutch company makes it, so it's likely available elsewhere too. Unfortunately, it says very little on the tin, except for mandatory large health warnings, so there are no exotic-sounding names of tobacco varieties in the blend or of far-away places where it was grown.

(A bit of a disappointment. Old Holborn proudly states on its packet: "It takes 25 varieties of premium grade tobacco, harvested from four continents, then cured gently and allowed to reach maturity, to produce the unique, full taste of Old Holborn Original." A much richer description; though it, too, is a Japan Tobacco brand, and there's likely more than tobacco in it.)

The seeds require warmth to germinate, but tobacco grows well in the UK.

Tobacco seeds and seedlings are tiny.

They grow fast.

Grow in pots, inside or outside; or grow outside in the ground.

Beautiful flowers

Beautiful roots

Beautiful leaves

Pressing and cutting

We read of and tried a method used by sailors, who used to wrap rope or twine around rolls of tobacco leaves to allow them to mature under compression. They cut slices from the end to smoke, rubbing the slices to open out the strands. This came to be called 'navy cut' tobacco.

Navy cut.

The two on the left are commercial cigarette rolling tobaccos. The one on the right is ours. It's OK for a pipe or cigar filler, but it needs to be much finer for cigarettes.

Buying seeds

We bought our tobacco seeds over the internet from Plantation House. We bought Maryland 609, Virginia and Monte Calme Yellow seeds; all suitably light for cigarette tobacco. There is a great deal of information on their site, as well as a forum of growers.

The law

The position with growing and using tobacco in the UK seems to be that if it's for personal use, no one's going to trouble you.

This is from a letter sent by Customs & Excise to Plantation House in October 2001:

There is not a great deal of home-grown tobacco smoked in the UK and we will certainly not be targeting potential domestic tobacco producers. Nor do we wish to devote a disproportionate amount of resource to the control of hobby growers and manufacturers.

You may wish to point out to your customers that duty only becomes due once the tobacco can be smoked, i.e. when the cured tobacco leaves have been shredded. There is no duty on tobacco seeds, which are quite legal to buy, or on the tobacco plants themselves.

Additive-free tobacco

A major consideration with growing your own tobacco is that it can be organically grown and additive-free.

In 2006, Gallaher listed on their site 366 additives to their cigarette tobacco. However, later that year they were taken over by Japan Tobacco, who don't list the info on their site (they state that that section of the website is currently under construction - at 22/04/09).

[Update 21st July 2011: The Japan Tobacco site now shows the ingredients added to tobacco. The info for the UK is here.]

If you are not growing your own and you want to smoke tobacco without additives, you can buy Free Jack Non-Additive Tobacco (that's 'non-additive', not 'non-addiCtive'). This one is sold in Spain, but a Dutch company makes it, so it's likely available elsewhere too. Unfortunately, it says very little on the tin, except for mandatory large health warnings, so there are no exotic-sounding names of tobacco varieties in the blend or of far-away places where it was grown.

(A bit of a disappointment. Old Holborn proudly states on its packet: "It takes 25 varieties of premium grade tobacco, harvested from four continents, then cured gently and allowed to reach maturity, to produce the unique, full taste of Old Holborn Original." A much richer description; though it, too, is a Japan Tobacco brand, and there's likely more than tobacco in it.)

24 Aug 2010

Ladybirds

Ladybird on yarrow stalk. (Doesn't look real, does it; but it is.)

Here's another. This one's by an elecampane seed head.

Here's another. This one's by an elecampane seed head.

23 Aug 2010

Making an earth oven. Part 2

Having finished the base, we made a door by glueing, dowelling and screwing together some lengths of thick wood that we had to hand. We used the door as the former for the tapered oven opening, with a smaller hardboard shape for the inside of the opening; then we built the arch of firebricks around these, using fireproof cement.

The wood used for the door. Four pieces glued and dowelled together.

The finished door.

Arch built around door.

The finished arch.

The inside shape for the oven is made from damp sand (we used bricks as well to save sand). This is covered with newspaper and dampened.

The sand former for the inside of the oven.

Sand former covered with wet newspaper.

The first core of the oven wall is built around the sand former. The mix is two-and-a-half parts sand to one of clay, packed down to make a four inch thick wall.

Using our old patio lamp reflector to aim the sun to dry the dark side.

When the clay and sand layer is pretty much dry, an insulation layer is built around it of straw mixed with sufficient clay to bond it; again four inches thick.

The mix for the insulation layer.

The sand and bricks are removed from inside the oven.

First fires to help drying out.

No chimney needed - draught goes in through the bottom, smoke comes out at the top. According to the book, this works because of the relative proportions of the oven and doorway.

Full fire burning to fully heat oven.

A temporary 'peel', as the flat wooden spade is called that is used to insert the dough and bring out the pizzas or bread, made here from two planks of cladding stapled together.

Cinders pushed to back and first pizza cooking.

Three minutes later.

Soda bread, baked for 20 minutes with cinders scraped out and with door in place.

We have more work to do to fully finish the oven. We have lime and sand here waiting for good weather so that we can apply a layer of finishing plaster. We need to use lime, because, like the clay, it breathes. Even then, though, the oven will not stand up to the English rain, so we have to make a cover, a roof, for it. Also, the breeze blocks at the front are to be clad with local stone. Waiting for sunshine.

We also have to finish the rockery behind the oven. It has been shaped to carry the water away from the oven and is to be planted with herbs, oregano in particular.

I had a lovely experience on the first day of lighting fires in the oven to help dry it out. In the evening, I lay on my belly over the clay of the oven with my arms round it and my cheek pressed against it, and felt the lovely motherly earth warmth and smell along with the scent of the straw in the clay. This straw smell brought back memories of pet guinea pigs and rabbits, and of days spent playing in barns with country cousins as a child. I didn't want to get up, so lovely was the feeling, and I lay like that for a long time, staring sideways at the late evening sky with a fir tree silhouetted against it.

Making an earth oven. Part 1

Making an earth oven. Part 3

See all Parts.

The wood used for the door. Four pieces glued and dowelled together.

The finished door.

Arch built around door.

The finished arch.

The inside shape for the oven is made from damp sand (we used bricks as well to save sand). This is covered with newspaper and dampened.

The sand former for the inside of the oven.

Sand former covered with wet newspaper.

The first core of the oven wall is built around the sand former. The mix is two-and-a-half parts sand to one of clay, packed down to make a four inch thick wall.

Using our old patio lamp reflector to aim the sun to dry the dark side.

When the clay and sand layer is pretty much dry, an insulation layer is built around it of straw mixed with sufficient clay to bond it; again four inches thick.

The mix for the insulation layer.

The sand and bricks are removed from inside the oven.

First fires to help drying out.

No chimney needed - draught goes in through the bottom, smoke comes out at the top. According to the book, this works because of the relative proportions of the oven and doorway.

Full fire burning to fully heat oven.

A temporary 'peel', as the flat wooden spade is called that is used to insert the dough and bring out the pizzas or bread, made here from two planks of cladding stapled together.

Cinders pushed to back and first pizza cooking.

Three minutes later.

Soda bread, baked for 20 minutes with cinders scraped out and with door in place.

We have more work to do to fully finish the oven. We have lime and sand here waiting for good weather so that we can apply a layer of finishing plaster. We need to use lime, because, like the clay, it breathes. Even then, though, the oven will not stand up to the English rain, so we have to make a cover, a roof, for it. Also, the breeze blocks at the front are to be clad with local stone. Waiting for sunshine.

We also have to finish the rockery behind the oven. It has been shaped to carry the water away from the oven and is to be planted with herbs, oregano in particular.

I had a lovely experience on the first day of lighting fires in the oven to help dry it out. In the evening, I lay on my belly over the clay of the oven with my arms round it and my cheek pressed against it, and felt the lovely motherly earth warmth and smell along with the scent of the straw in the clay. This straw smell brought back memories of pet guinea pigs and rabbits, and of days spent playing in barns with country cousins as a child. I didn't want to get up, so lovely was the feeling, and I lay like that for a long time, staring sideways at the late evening sky with a fir tree silhouetted against it.

Making an earth oven. Part 1

Making an earth oven. Part 3

See all Parts.

Making an earth oven. Part 1

After having a delicious pizza cooked in just a few minutes in my nephew's breeze block pizza oven, I wanted to be able do this.

There are plenty of drawings, sketches and photos covering all aspects of the task, as well as a section on making bread. All dimensions, proportions and materials are given, as well as info on earth ovens used around the world.

The base

First stage is construction of the base, which is well insulated using empty bottles and jars packed together with a clay and straw mixture. (we particularly like one brand of coffee here, so its jars made up the bulk of the insulation.)

The insulated base will help retain the heat in the oven floor (for crispy bases on pizzas).

Digging out the bank and laying a foundation (shaped with a length of plastic bent into a curves and pegged in position). The metal disk is the top of a patio lamp that fell over and broke. It's used here as a guide because it's the approximate diameter that the oven will be.

Breeze block wall to contain the base insulation. Paving slabs for seats, with fuel wood storage under them.

We have a lot of clay here below the topsoil, so the main material was right on hand.

Pummel the dried clay to smash the lumps. (Makes mixing easier.)

Clay mixed with water.

Helpers are willing.

Insulation mix: wet clay mixed with wood chips. Wood chips, shavings, straw - any would do the job.

The base is filled with empty glass bottles and jars (with lids removed) packed together with the insulation mix.

The area under the oven floor is to be four inch thick solid clay, so we ringed that area with a plastic strip to act as a mould for the clay. Bottles and insulation mix were packed around the oustide of the ring.

(The insulation board seen in the picture is some that we used for edges because we had it handy, left over from a previous job.)

Ready for the clay pad.

The pad set. Cracks are inevitable. We filled them afterwards.

A thick layer of clay spread over the top. This brings the level up ready to receive the firebricks for the oven floor.

More cracks.

Firebricks laid for the oven floor then, around them, outside the oven floor itself, rocks that have been dug up from the ground here.

Making an earth oven. Part 2

Making an earth oven. Part 3

See all Parts.

Subscribe to:

Posts (Atom)